Join the Journey.

DRIVEN BY INSPIRATION AND EXPERIENCE

BUILDING OUTSTANDING MACHINE TOOLS AND VISES

We are convinced that nothing is impossible. Thinking and acting unconventionally is therefore part of our corporate DNA. This allows us to develop machine tools and clamping technology that not only meet the high demands of our markets, but also secures real competitive advantage for our customers – anywhere, anytime.

Whether for the bandsaw, industrial gear rack or automotive industry, our drive and passion for inspired engineering has allowed us to deliver world-class milling, grinding and setting machines and machine tool vises for over 130 years. In our design offices and manufacturing locations, our innovations are continually setting new standards. Moreover, one thing is for sure: redefining what is possible is something we will never stop doing.

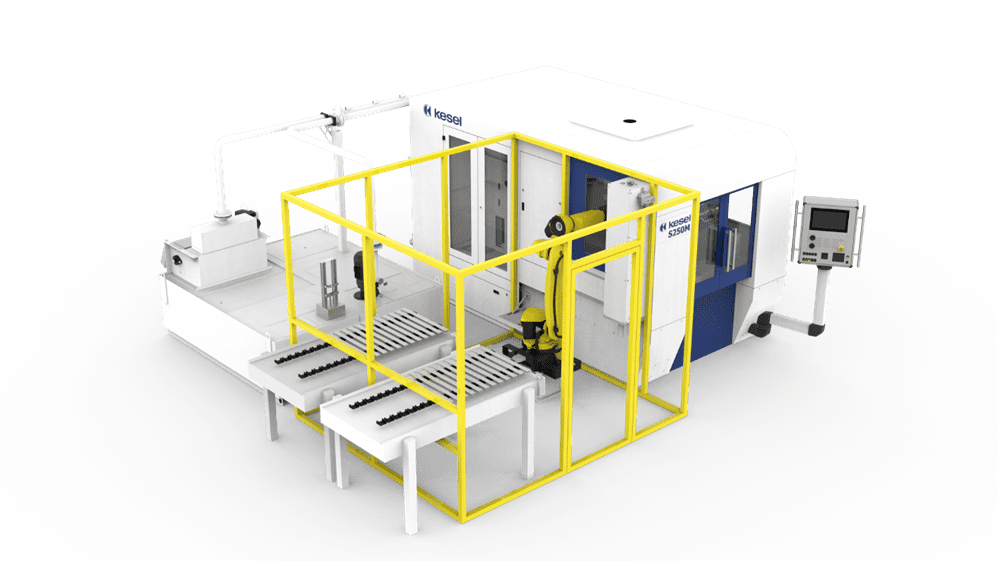

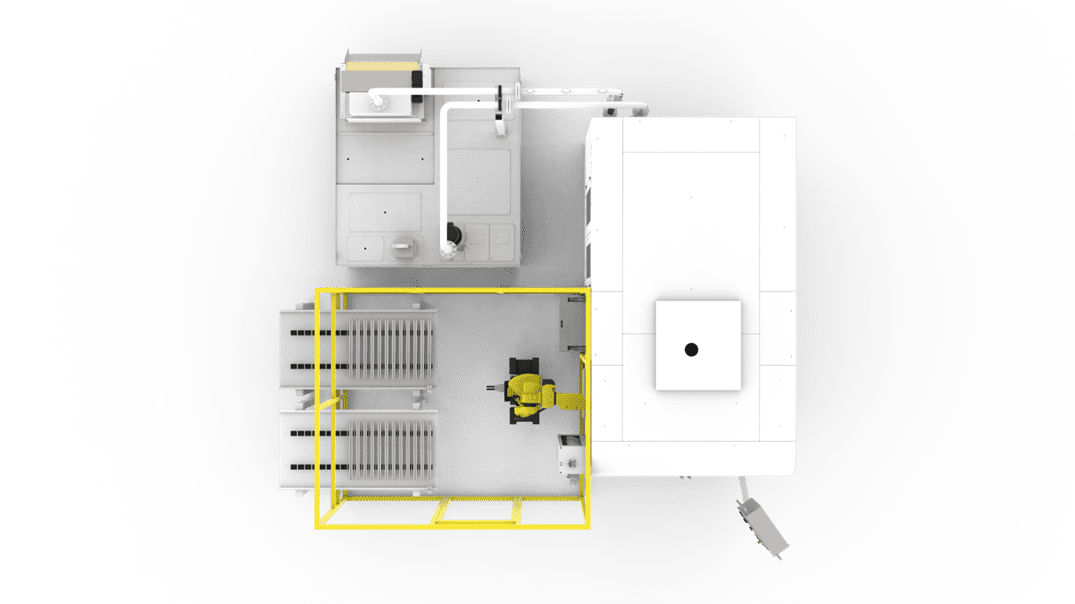

Productivity and Precision

The S250M steering rack milling machine delivers on all fronts. With a focus on world-class quality our team of engineers have designed our latest steering platform to achieve the highest standards of precision within a system that is designed to minimise cost per part.

- For single and dual pinion racks

- Fully automated solutions

- The new F1-HSK milling head

What makes Kesel Different?

Take our latest pneumatic vise, the ZSP, for example. Our team of engineers do things differently. They listen to our customers. They draw on their experience. They are driven by inspiration. All of this combines to result in world-leading solutions for work piece clamping and holding. The ZSP not only delivers phoenmenal clamping performance, it has been designed to integrate seamlessly alongside automated systems. The result? Quality that supports and drives your productivity.

Discover VisesFAQ

What defines a Kesel vise?

Our vises and clamping technology is defined by quality, performance and precision. We know our products are investments and therefore we build them to not only deliver performance, but to do so for many many years.

Who uses Kesel machine tools?

Our machine tools are primarily used within the bandsaw, industrial gear rack and automotive industries. We do, however, support many other customers with linear toothing requirements across the metal forming world.

Where are Kesel machine tools and vises manufactured?

'Made in Germany' isn't just a marketing term at Kesel, it reflects fact. All of our machine tools and vises are manufactured at our headquarters location in Bavaria, Germany.

Who are Kesel?

Put simply, we are a German machine tool and clamping technology manufacturer. We were established in 1889 and have been engineering ever since. We are lead by our managing director Jean B. Christ and are part of GESCO SE, a German investment group focused on technology.

What technologies do you provide?

We manufacture milling, grinding and setting machines as well as coiling systems for band steel. We design and engineer the entire spectrum of clamping solutions from manual, hydraulic and pneumatic vises through to custom solutions for complex parts.

Where are Kesel located?

Our headquarters is in Kempten, a city in the southern German state of Bavaria. We also have service and support locations in Wisconsin, USA and Jiashan, China.

Have a question? We're here to help.

To our Knowledgebase Customer Service & Kesel Connect

Customer Service & Kesel Connect

.webp)