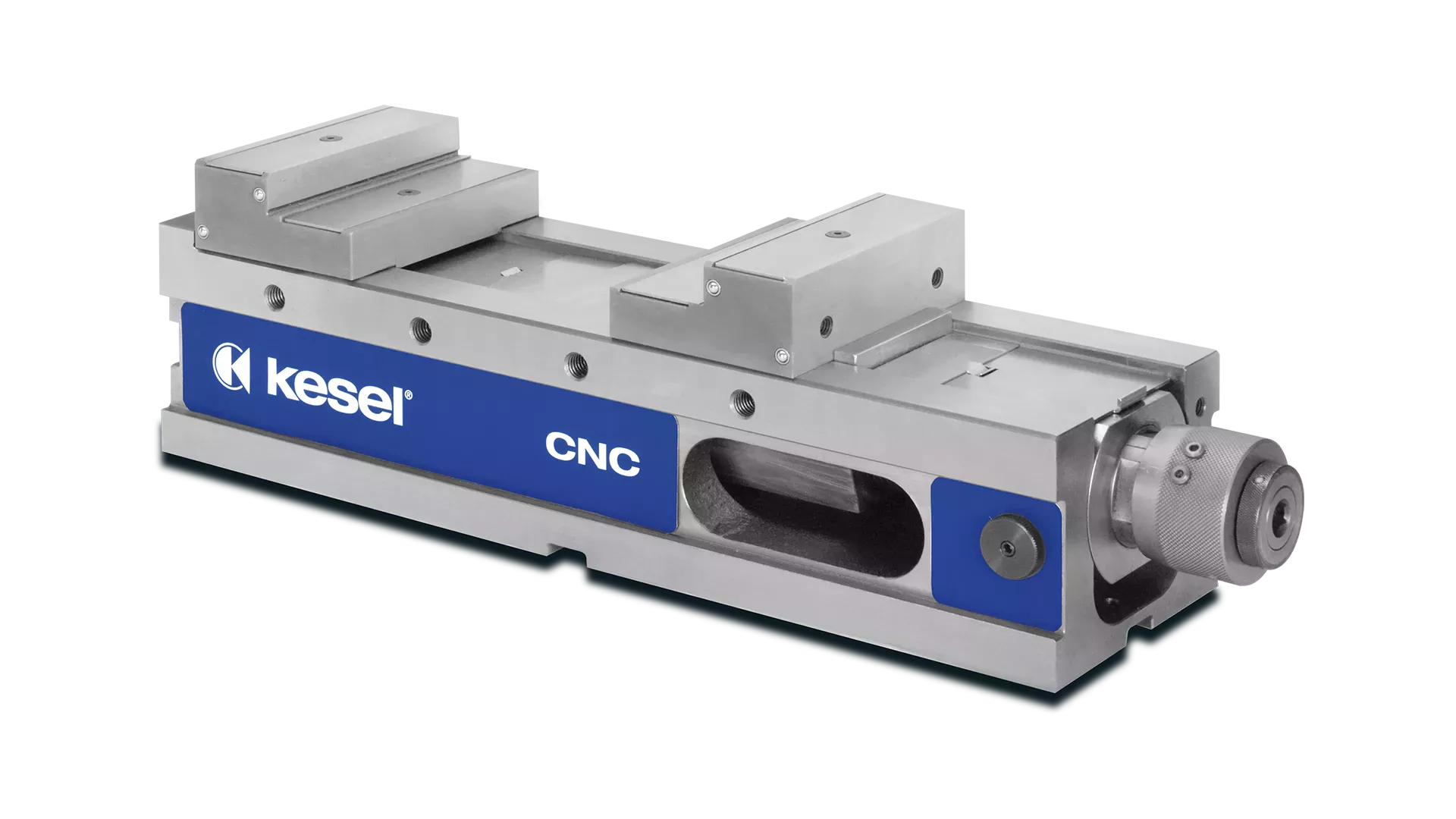

High Pressure Vise

CNC

| Jaw width: | 91 - 125 mm, 126 - 200 mm |

|---|---|

| Processing: | conventional processing |

Fine-step clamping force preselection, direct clamping without force booster is also possible

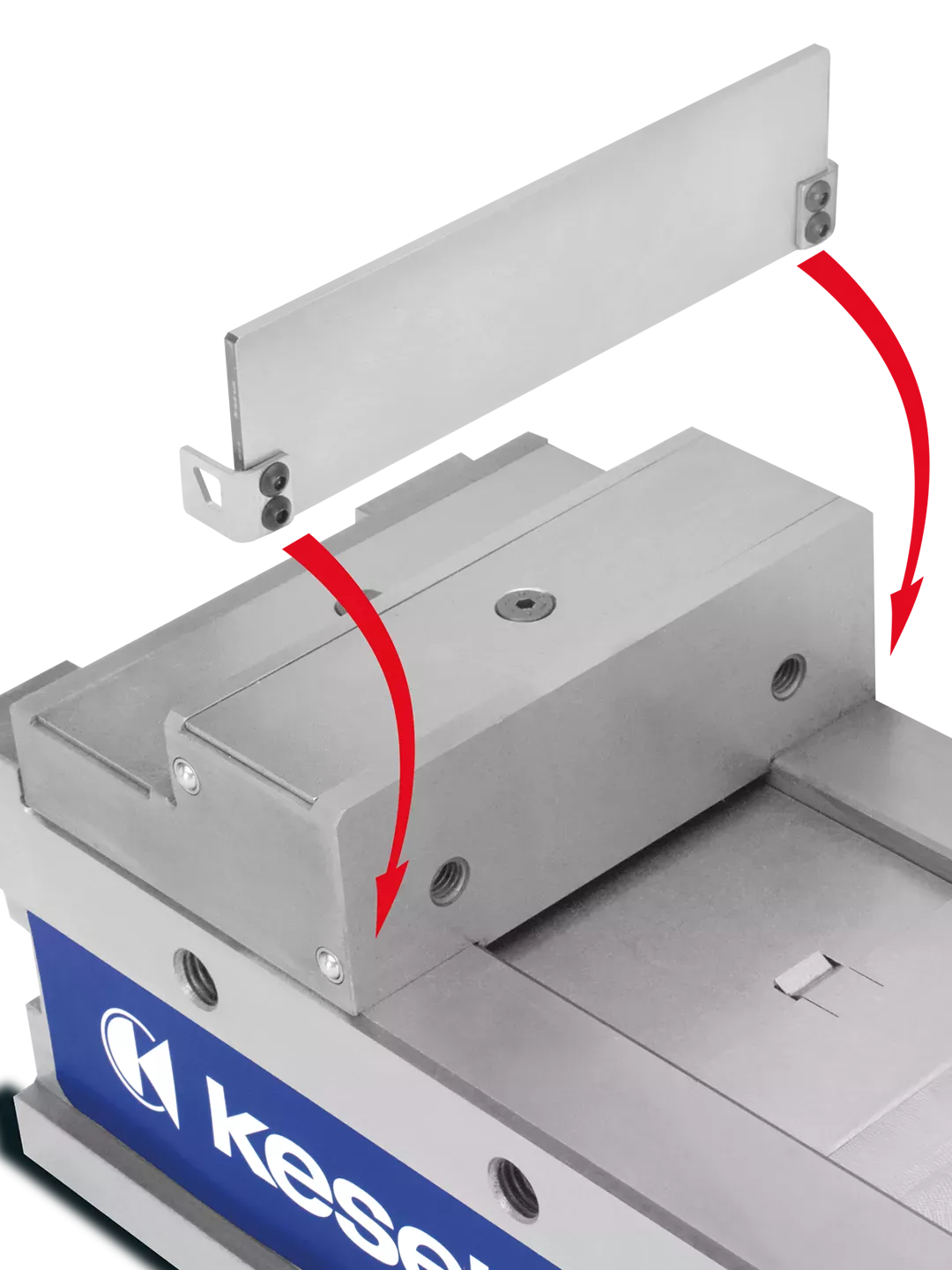

Quick jaw change due to the patented quick-change system

Spindle can be removed within 10 s. allowing access to the fixing screw.

- Optimum chip protection of the high-pressure spindle through patented wiper technology and covers

- Alignment possible through longitudinal and transverse grooves as well as via 0-point clamping systems

- Scope of delivery: incl. 4 clamping claws, 1 hand crank

Any questions?

Contact Sales DepartmentIn Action!

360° View

FAQ

How does the quick-change jaw system work on a high-pressure machine vise?

When changing the jaws of the CNC High Pressure Machine Vise, it is not necessary to unscrew 4 screws completely, but only 2 screws by 1 turn. Then the jaw can be pulled off over the screw head and changed.

Does the CNC High Pressure Machine Vise have a power amplifier?

Yes, the integrated force amplifier makes it easy to achieve a high clamping force. The clamping force can be reproduced easily and with good repeatability thanks to the finely graduated force adjustment.

What is the advantage of the quick extraction of the spindle in a high-pressure machine vise?

By removing the spindle on the CNC High Pressure Machine Vise it is then easy to the screw the base body to the table and also allows easy cleaning of the vise.

Can the jaws from the Kesel CNC High Pressure Machine Vise also be used with the Kesel NCA?

No, these 2 vises are not compatible.

What is the purpose of the threads in the jaws and on the side of the base body of the CNC high-pressure machine vise?

Various jaws types can be screwed into the jaw threads of the CNC. A workpiece stop can be attached to the threads on the base body.

What are the steel ball-bearings in the jaws used for?

These are spring-loaded pressure points. Our Kesel step ledges (support ledges) can be clicked into these.

Any questions. We will help you

Knowledgebase Customer Service & Kesel Connect

Customer Service & Kesel Connect