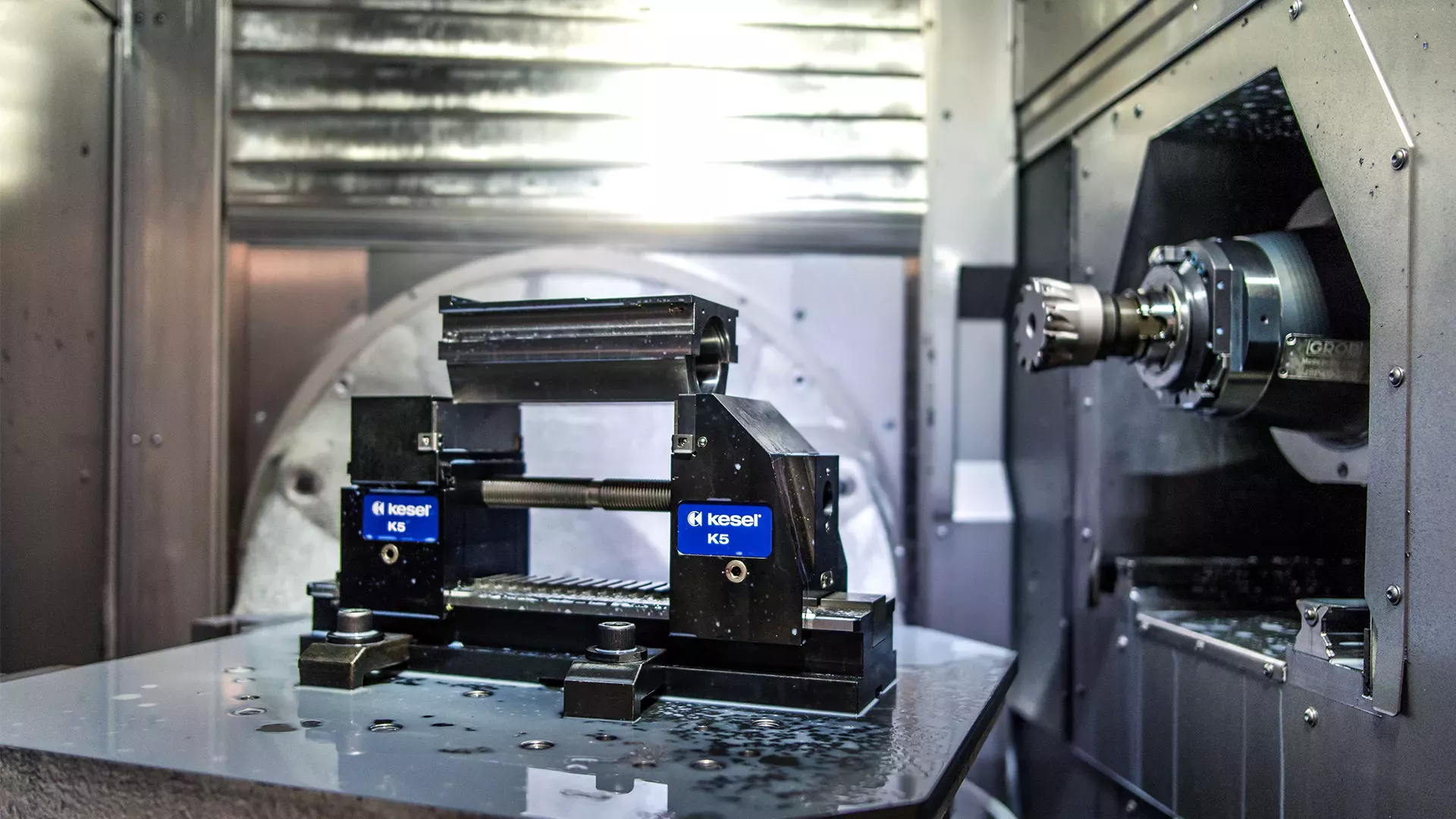

Machine Tool Vise

K5

| Jaw width: | 91 - 125 mm |

|---|---|

| Processing: | 5-Axes processing, conventional processing |

Optimum accessibility for 5-sided machining

Flexibility due to large 16 mm clamping stroke

Quick adjustment of the clamping width

- Preloaded system: highly accurate, no vibrations

- Flexible jaw programme

Any questions?

Contact Sales DepartmentIn Action!

360° View

FAQ

Can the fixed jaw be adjusted?

Yes, the fixed jaw can be placed individually on the base body. This provides optimum accessibility to the workpiece.

Why does the K5 machine vise have a " pre-tensioned " system?

The pretensioned system on the K5 greatly increases the rigidity of the clamping.

This avoids vibrations and improves accuracy.

When clamping small parts, do the ends of the spindle protrude from the vise?

No, the K5 is delivered with a long and a short spindle. These can be easily exchanged, depending on the span.

How does the indexing system work on the K5 machine vise?

Using a Allen key, a locking bolt can lock or unlock the jaw of the K5 in the desired span on the locking rail.

How do you clamp the K5 machine vise?

Workpieces can be clamped on the machine vise using a torque spanner and the supplied Allen key.

What are the steel ball-bearings in the jaws used for?

These are spring-loaded pressure points. Our Kesel step ledges (support ledges) can be clicked into these.

Any questions. We will help you

Knowledgebase Customer Service & Kesel Connect

Customer Service & Kesel Connect