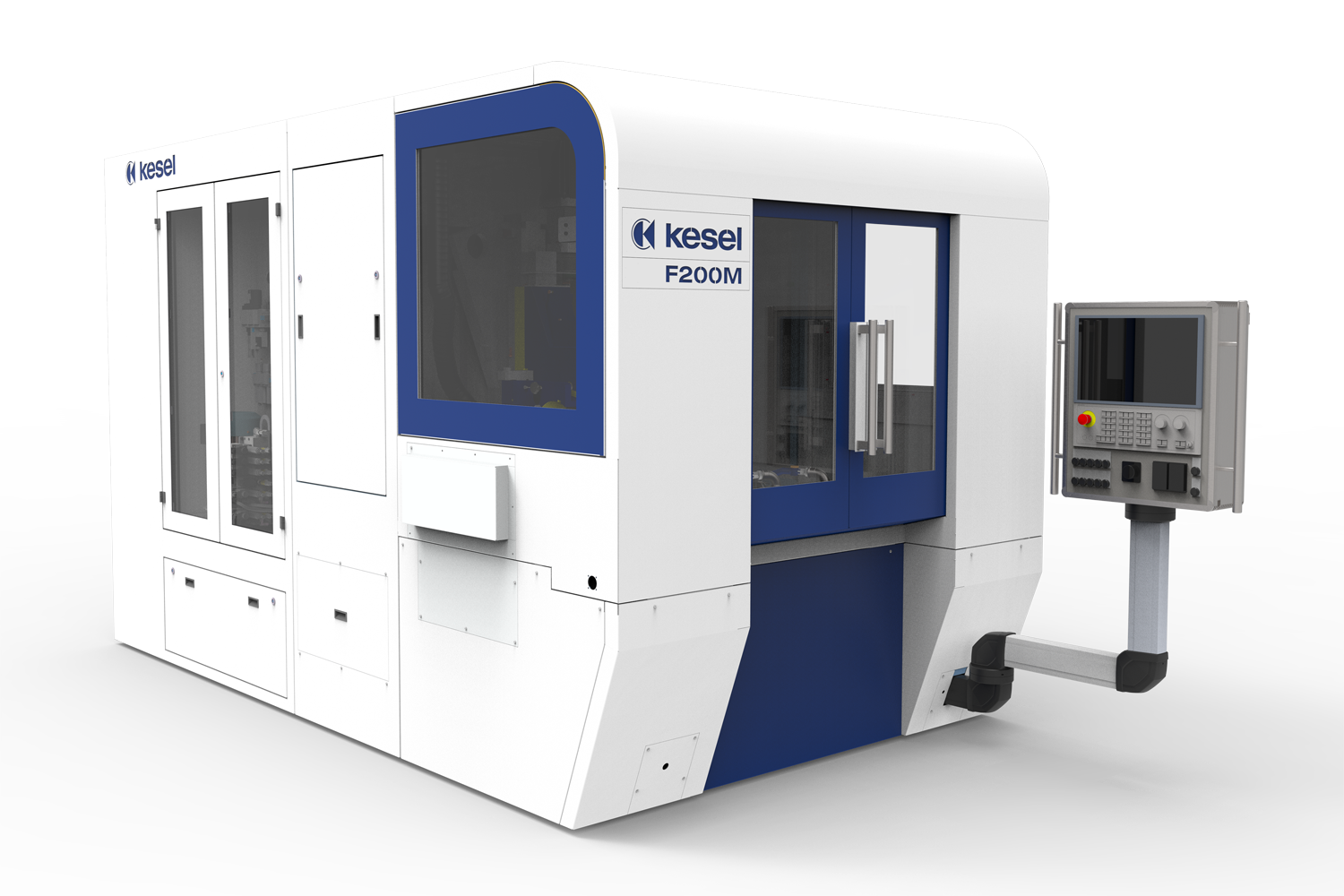

Steering Rack Milling Machine

S250M

Supplied with its own custom coolant management system the S250M offers a compact, flexible solution to high volume steering rack manufacturing. And with the ability to change the tooling in a matter of minutes, machine uptime as well as part flexibility can be maintained at all times.

The S250M. A new era begins.

| Industry: | Automotive, Gear Rack |

|---|---|

| Technology: | Milling |

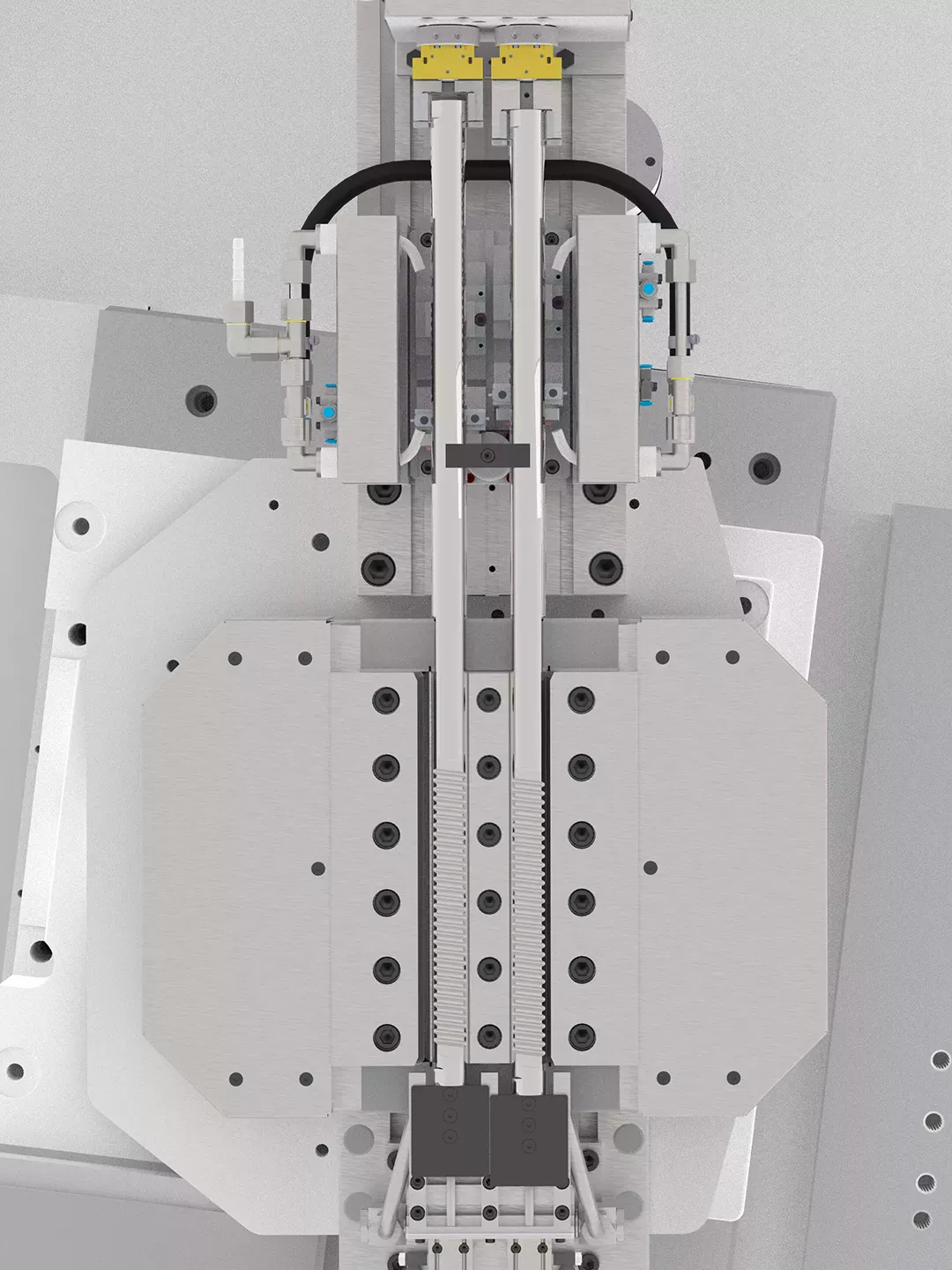

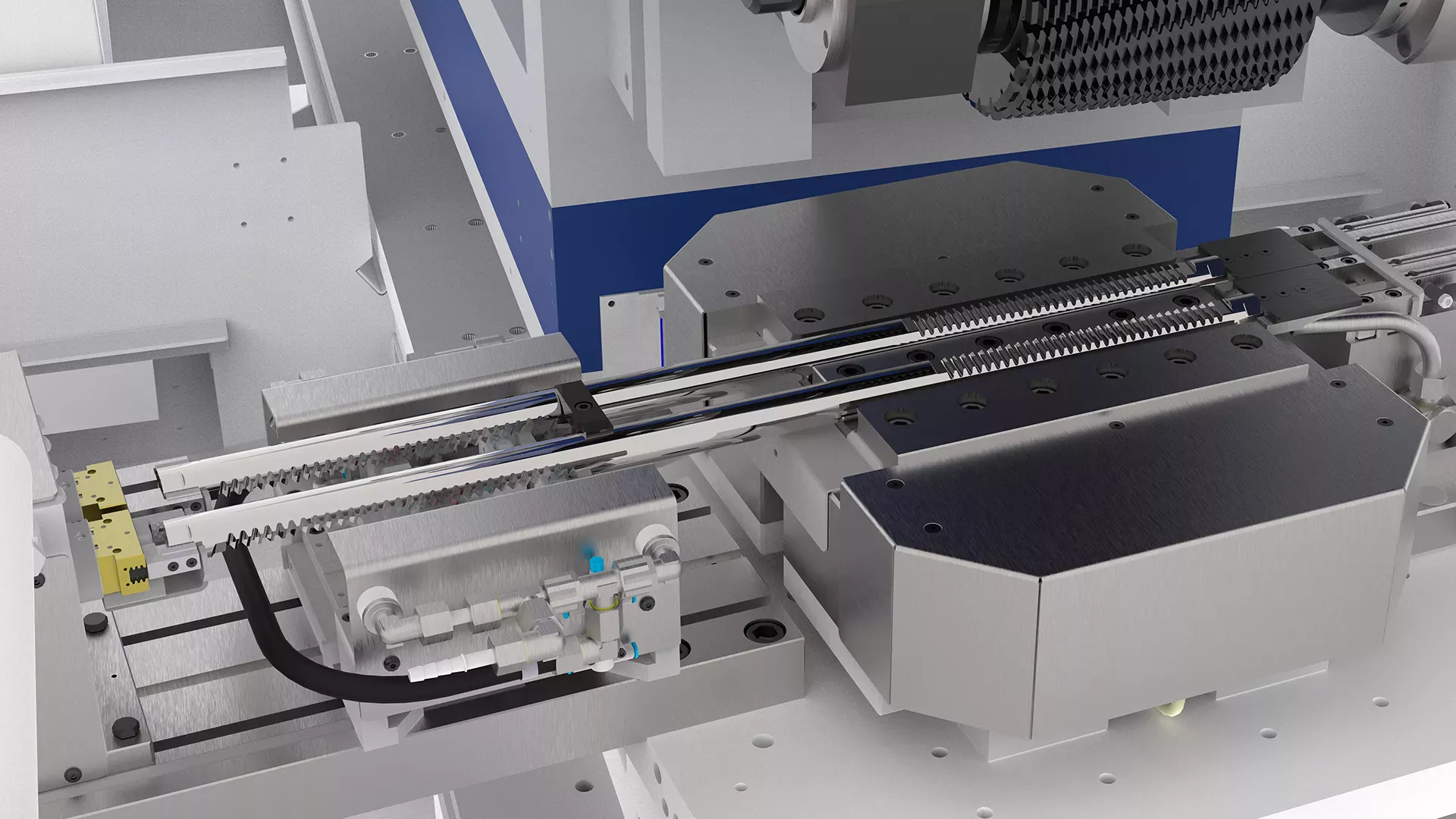

A completely redesigned machine platform for productivty and precision.

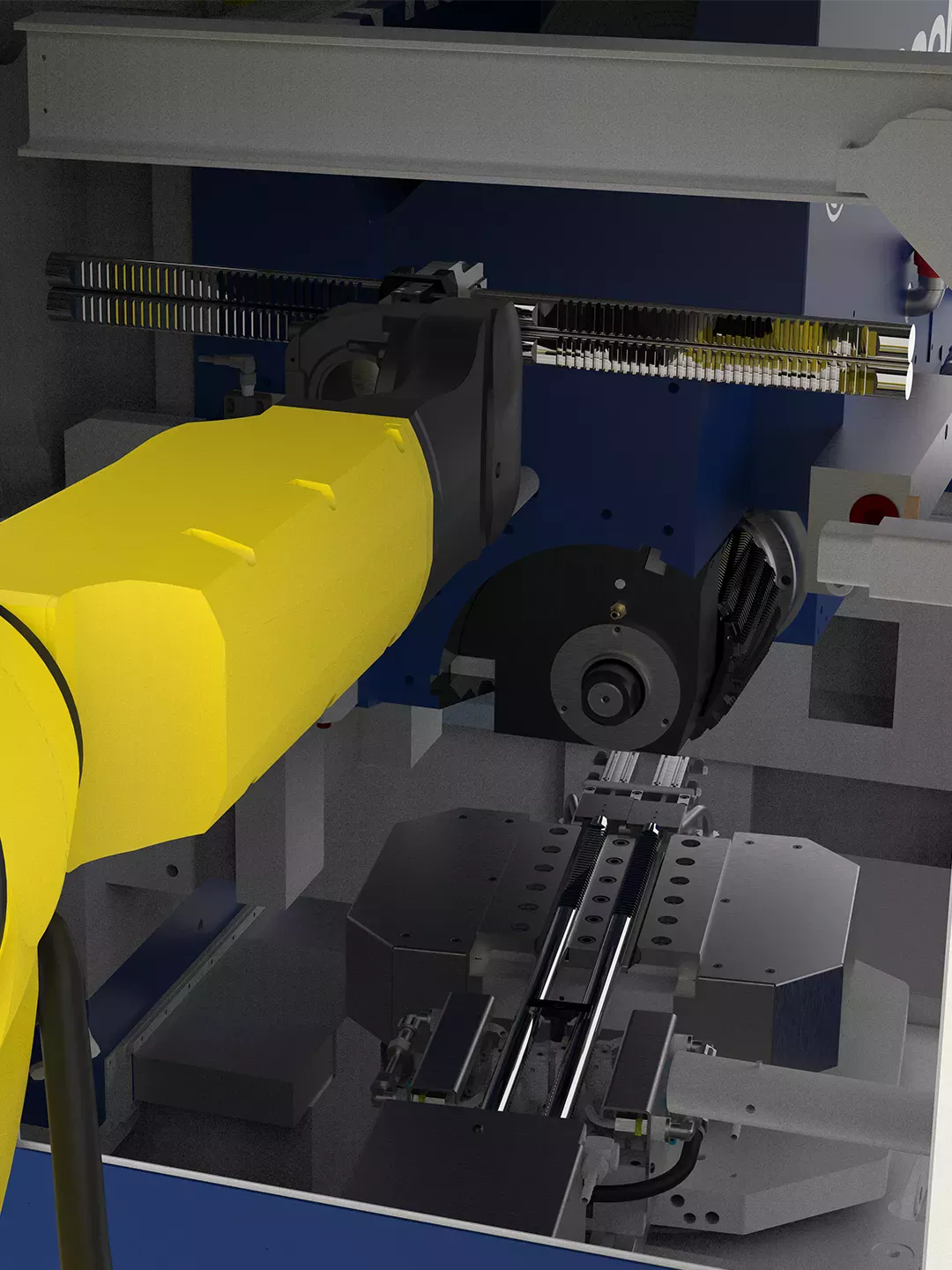

Fully automated solutions for single and dual pinion manufacturing.

A brand new milling head for even higher performance!

Fully automated loading systems.

Complete dual pinion manufacturing cell."

Any questions?

Contact Sales DepartmentIn Action!

FAQ

How many racks can I clamp in the Steering Rack Milling Machine S250M?

Both our standard and twin-A1 axes can clamp 2 racks simultaneously for maximum productivity.

Can the Steering Rack Milling Machine S250M mill the toothing on ballscrew racks?

Yes! As well as standard single pinion, the Steering Rack Milling Machine S250M can also mill ballscrew and dual pinion racks.

Can the Steering Rack Milling Machine S250M mill both toothings on a dual pinion rack?

Yes. With the use of our twin-A1 axis that is possible. For mass production we have also developed a 2-station, stand-alone cell which mills dual-pinion racks with fully automated handling.

What coolant medium is used with the Steering Rack Milling Machine S250M?

We use oil as standard in the Steering Rack Milling Machine S250M. This provides optimal surface finish and lubrication which supports longer tool life.

What experience do Kesel have in the automtive industry?

We have been working alongside Tier 1 automotive suppliers for many decades. This has given us an intimate understanding of the industry's requirmeents. We have machines worldwide at almost every leading manufacturer.

Is milling an effective process?

Milling steering racks offers the very best combination of productivity, precision, flexibility and investment. Continual market feedback has confirmed this year after year.

Any questions. We will help you

Knowledgebase Customer Service & Kesel Connect

Customer Service & Kesel Connect