Machine Vise

Bull (Mech)

| Jaw width: | 91 - 125 mm |

|---|---|

| Processing: | conventional processing |

Precisely repeatable clamping force through use of a torque wrench

Durability due to encapsulated spindle

Large clamping width when used with stepped jaws

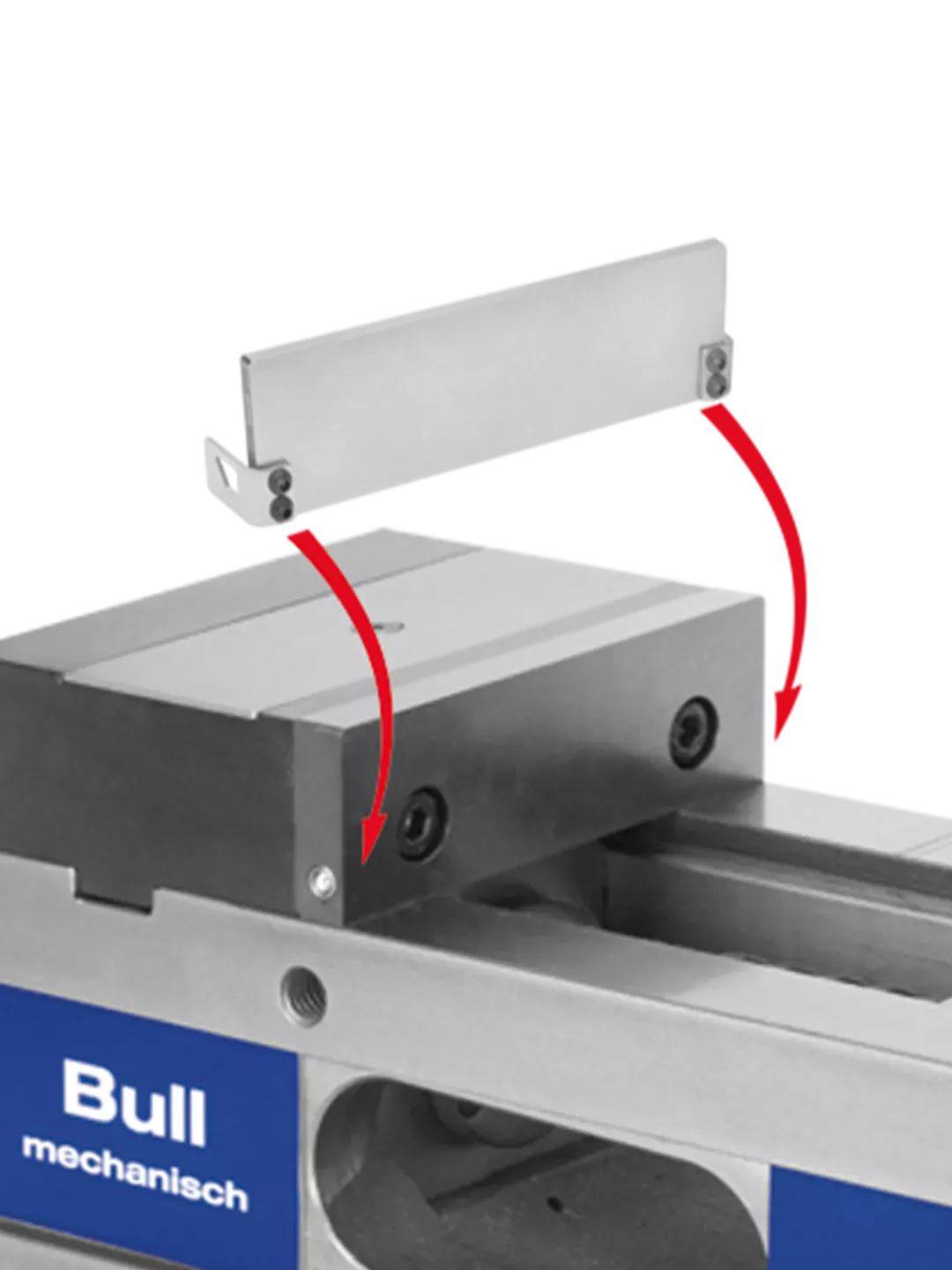

- Integrated quick-change step bar system

- Compact design, constant overall length

- Stable base body made of ductile cast iron GJS-600

Any questions?

Contact Sales DepartmentIn Action!

360° View

FAQ

How does the patented quick adjustment of the clamping width work on a mechanical machine vice?

The locking lugs on the spindle can be turned downwards by 180° by hand.

Then the movable jaw can be moved and locked in the desired position.

Adjustment to the workpiece and clamping is done with a 1/2" square torque spanner.

Do chips that fall into the vise cause problems?

No, the chips can be flushed out of the vise through the large elongated holes on the side or on the face of the fixed jaw.

In addition, the spindle is protected against chips with highly effective seals.

Does the Bull (Mech) Machine Tool Vise have a clamping force adjustment?

It is clamped with a torque spanner. The clamping force increases linearly with the set torque to max. 40 kN at max. 105 Nm.

Can the Bull (Mech) Machine Tool Vise be converted into a pneumatic vice?

Yes, with the spindle from Bull Pneumatik + a new fixed jaw, the vice can be converted into a pneumatic version.

Can the clamping block (carriage) be rotated?

Yes, the clamping block can be pulled out with the jaws to the rear and pushed in again rotated by 180°. This allows the sap width to be changed very quickly.

What are the steel ball-bearings in the jaws used for?

These are spring-loaded pressure points. Our Kesel step ledges (support ledges) can be clicked into these.

Any questions. We will help you

Knowledgebase Customer Service & Kesel Connect

Customer Service & Kesel Connect