Pneumatic Centering Clamp

ZSP

| Jaw width: | 91 - 125 mm |

|---|---|

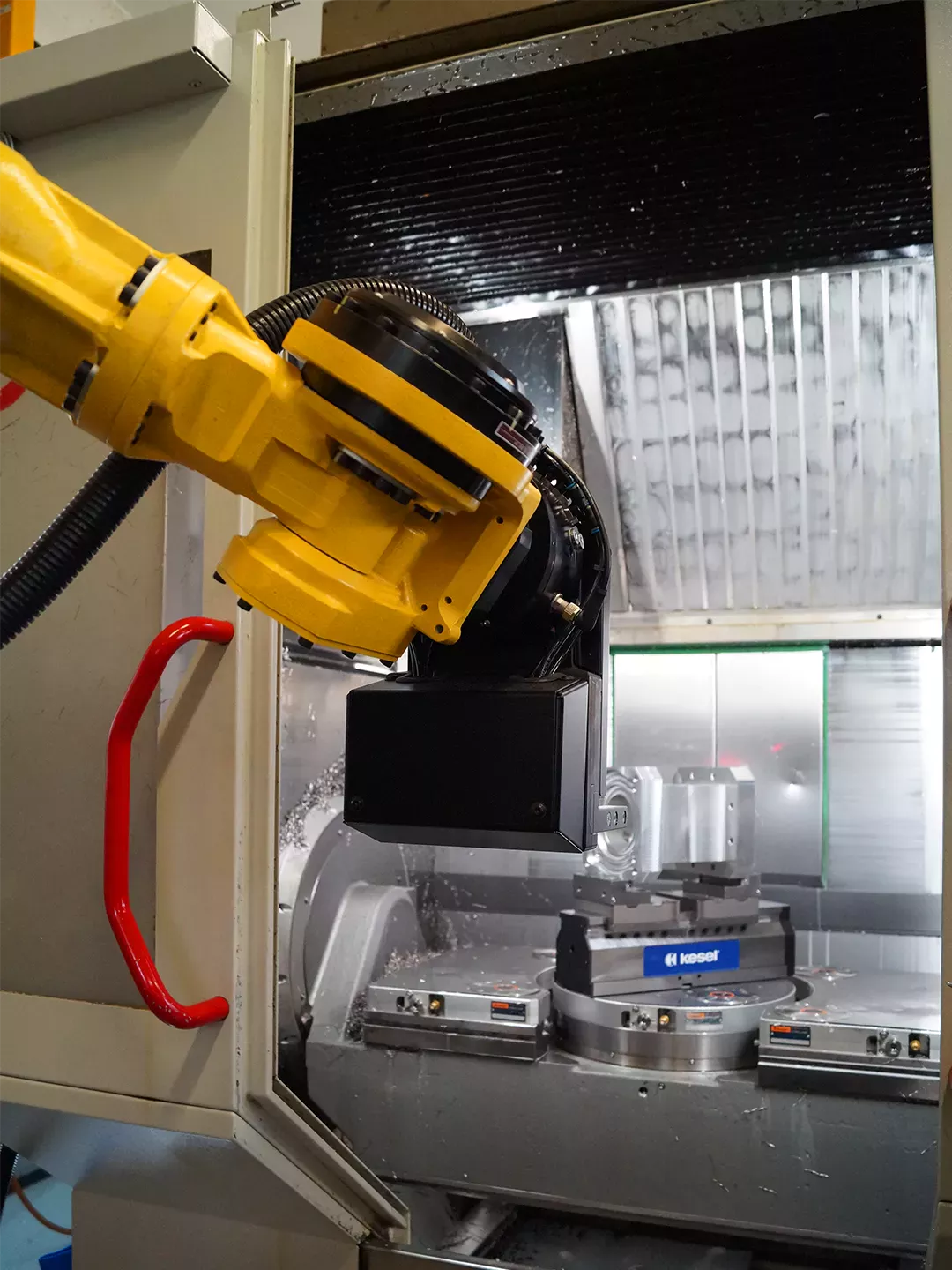

| Processing: | Automation |

Optimum tool accessibility

Huge adjustment range (90 mm)

Large clamping stroke (5 mm)

• Large adjustment range of the clamping width (12 mm - 291 mm)

• ‘Chip-free’ and low-maintenance due to the encapsulated design

Any questions?

Contact Sales DepartmentIn Action!

360° View

FAQ

How does the clamping width adjustment work on a pneumatic vise?

The clamping width of the ZSP can be easily and quickly adjusted with the supplied Allen key.

Where and how is the compressed air connected on a pneumatic vise?

The compressed air for the ZSP Pneumatic Centering Clamp can be connected to either the front of the vise or the bottom, with an additional base plate.

Which pneumatic accessories are needed?

This varies greatly depending on the application. Please ask our Kesel service team, we will be happy to put together the pneumatic accessories you need.

What clamping stroke does the ZSP Pneumatic Centering Clamp achieve?

A maximum clamping stroke of 5 mm is generated with the pneumatic centring clamp ZSP; the workpiece is clamped symmetrically with both jaws.

What about clamping reliability in the event of compressed air loss?

The installation of a check valve in the compressed air line prevents a drop in the clamping force.

What are the steel ball-bearings in the jaws used for?

These are spring-loaded pressure points. Our Kesel step ledges (support ledges) can be clicked into these.

Any questions. We will help you

Knowledgebase Customer Service & Kesel Connect

Customer Service & Kesel Connect