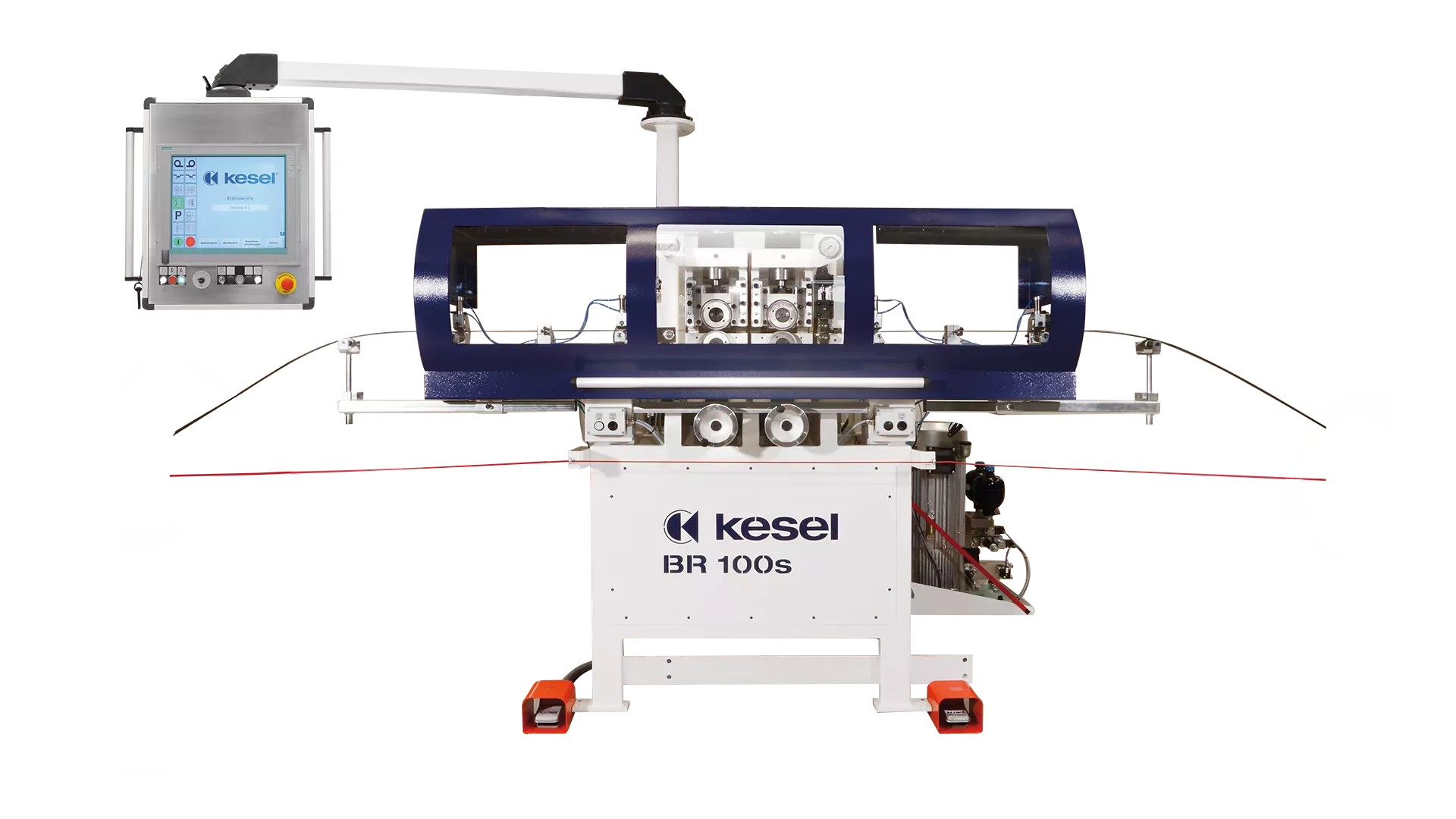

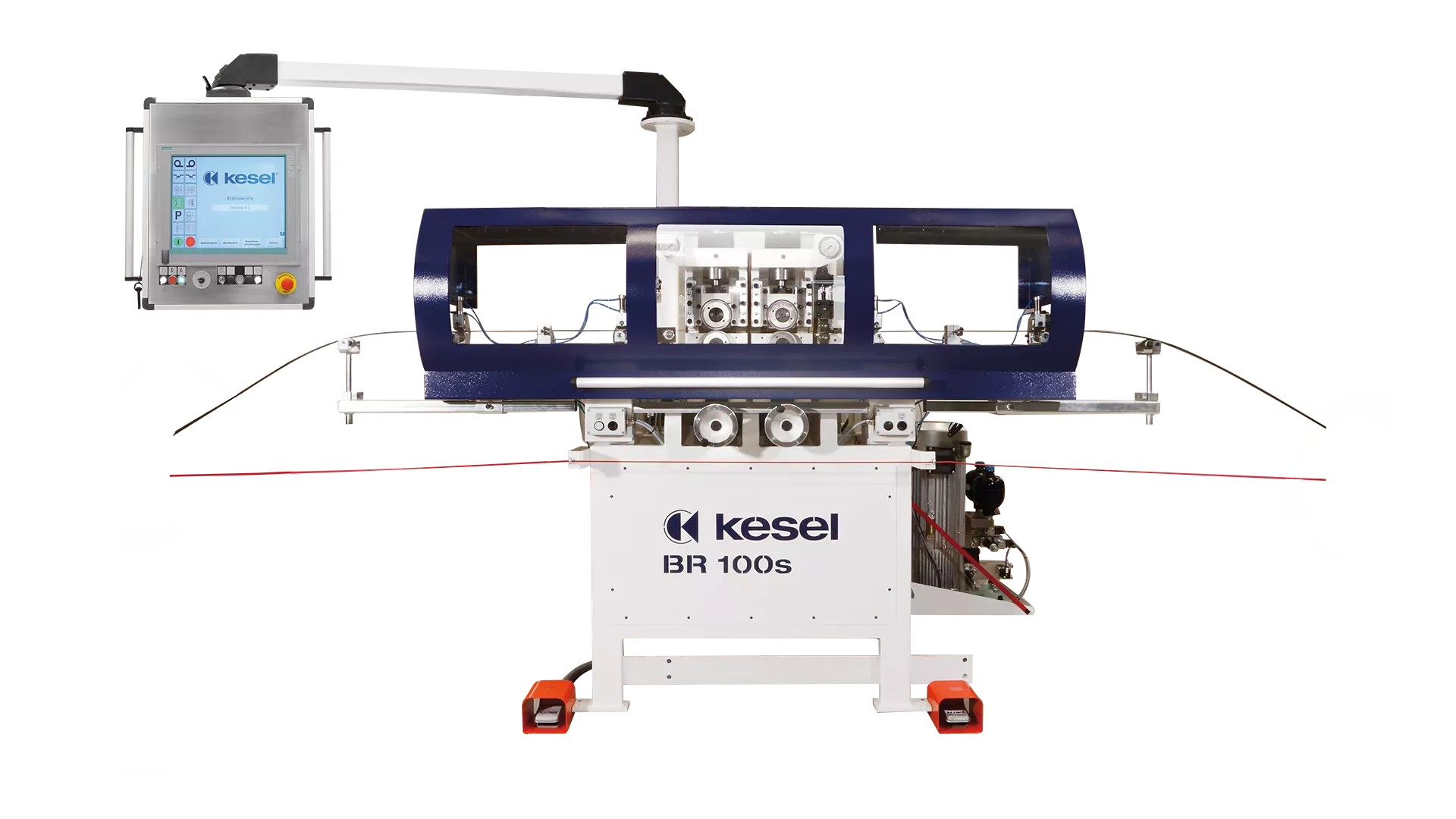

Band Straightening Machine

BR 100s

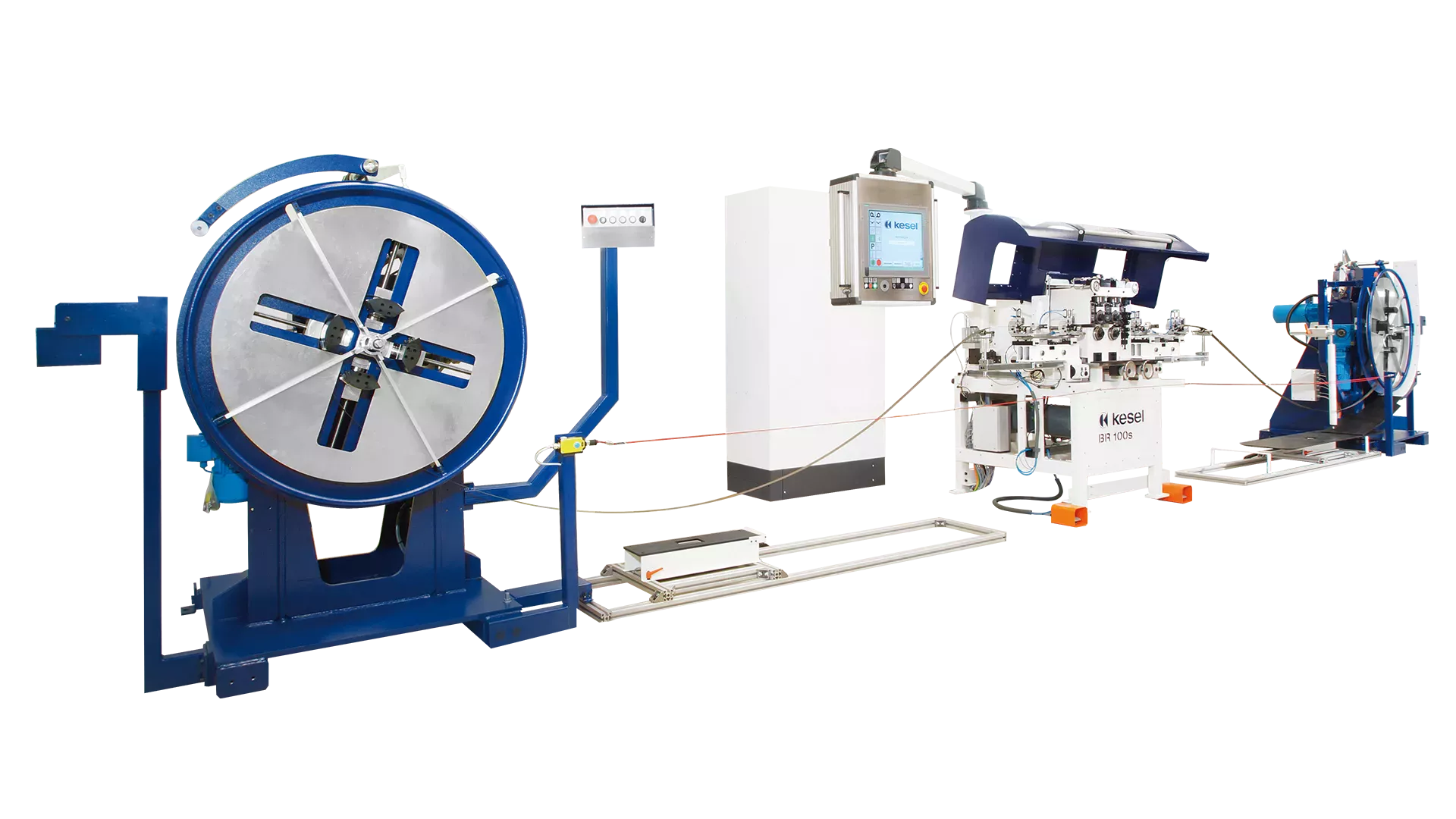

With optional titling pay-out and take-up units and integrated slack monitoring, material handling and transportation is seamless. And with the ability to export a digital straightening protocol the BR 100s can also form a valuable part of your QC management system.

| Industry: | Bandsaw |

|---|---|

| Technology: | Straightening |

The BR 100s not only straightens but can also create defined cambers at the touch of a button.

The BR 100s integrated teach-in function optimises speed and productivity.

The unique tilting coiling system ensures rapid coil changeovers.

Machine can be configured for left or right-hand feed direction."

Any questions?

Contact Sales DepartmentIn Action!

FAQ

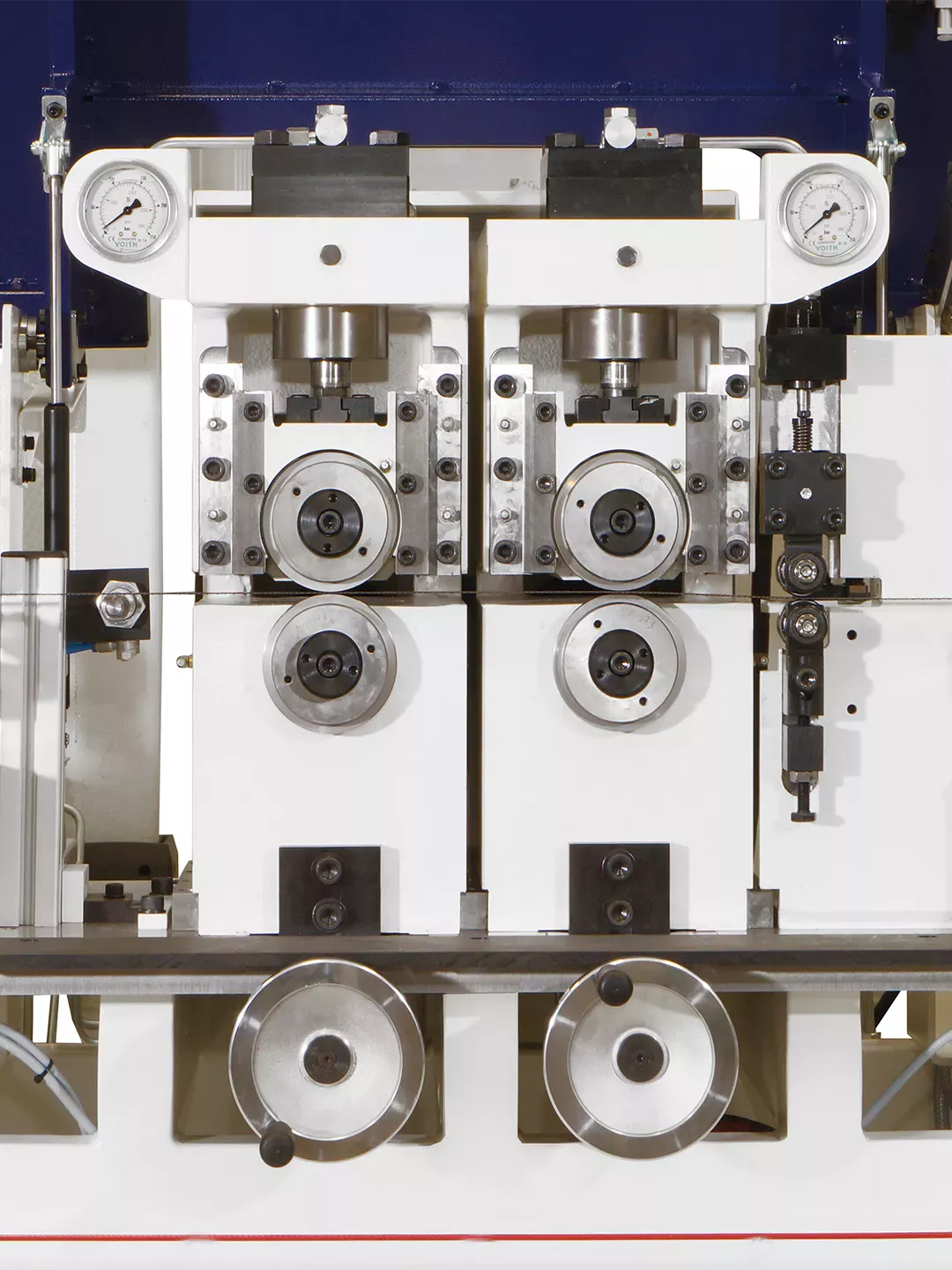

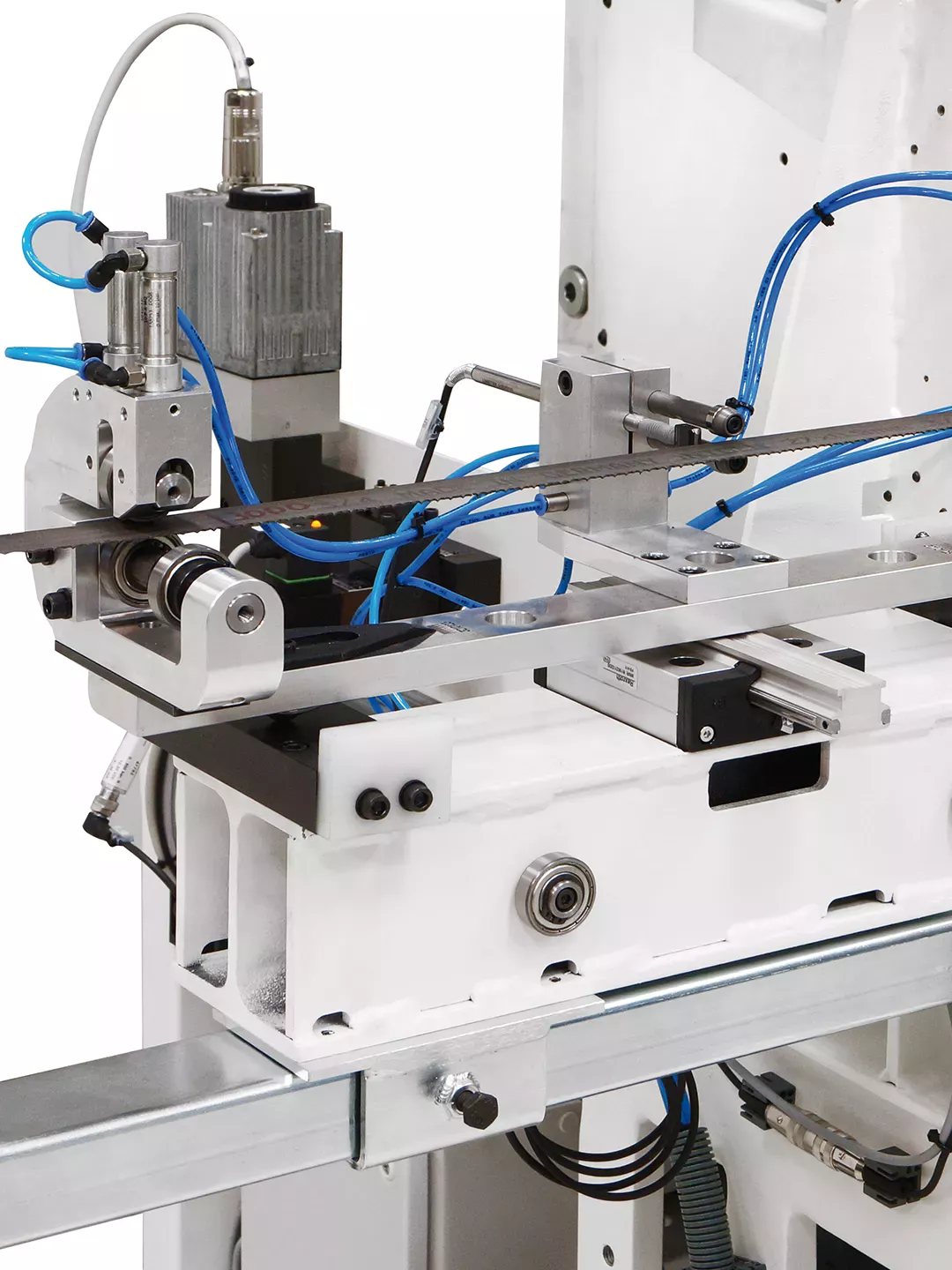

Can the Band Straightening Machine BR 100s straighten toothed material?

Yes. The Band Straightening Machine BR 100s can straighten toothed or un-toothed material. The straightening mechanism is designed to ensure the toothed edge is protected at all times.

Can the Band Straightening Machine BR 100s create a camber in material?

As well as straightening material the Band Straightening Machine BR 100s can also create a defined camber. This can support bandsaw products where a short in the tooth is required.

How accurate is the Band Straightening Machine BR 100s?

The Band Straightening Machine BR 100s can straighten or create cambers to tolerances of < 0.5 mm/m.

At what speed can the Band Straightening Machine BR 100s operate?

This is dependent on the band material and degree of camber but our recommended maximum operating speed is 40 m/min.

Is the Band Straightening Machine BR 100s easy to use?

Really easy! The Band Straightening Machine BR 100s has been designed with the operator in mind and is very much a 'plug and play' machine. With the tilting coiling systems and integrated 'teach-in' function the BR 100s is easy to use and requires minimal operator input.

Does the Band Straightening Machine BR 100s have remote diagnostic capability?

Yes. Like all of our machines the Band Straightening Machine BR 100s is supplied with an integrated system specifically to allow remote access. This allows our team to support you directly on your machine wherever you are in the world.

Any questions. We will help you

Knowledgebase Customer Service & Kesel Connect

Customer Service & Kesel Connect